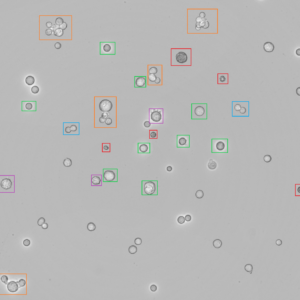

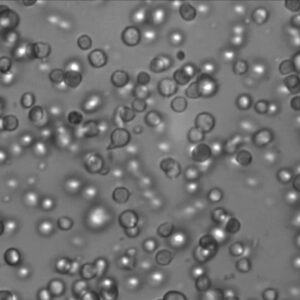

CELL COUNT / VIABILITY / SIZE

Cell Analysis and particle size analysis range in a linear flow or recirculating loop. This system is designed for lab and inline use with varying pressures and temperatures.

CELL ANALYSIS

FERMENTATION

Canty imaging systems significantly enhance fermentation processes by providing detailed, real-time insights into the culture environment by measuring key parameters such as cell size, concentration, and viability directly during fermentation.

FERMENTATION

FILTER CONTROL

Monitoring turbidity with CANTY’s high resolution CCD/CMOS image sensors can signal unwanted particles in the filtrate caused by filter malfunction.

FILTER CONTROL

FOAM AND LEVEL DETECTION

CANTY Camera and Light Vision Systems are a patented design to view and illuminate the inside of a pressure or process vessel through a single connection. There is no need for multiple ports! CANTY can supply an integrally mounted camera and light (optional) in flanged, sanitary or NPT threaded process connections. CANTY fused glass technology provides a safe, high pressure, hermetic fused glass barrier between the process and the camera electronics.

FOAM & LEVEL DETECTION

TURBIDITY / LIQUID ANALYSIS / CIP

Liquid analysis using a high resolution CCD/CMOS image sensor that detects turbidity changes in fluids by measuring the transmittance of light. Using advanced software algorithms the system automatically removes gas bubbles from the analysis resulting in highly accurate and repeatable data outputs. This system is designed for inline use with varying pressures, temperatures, and pipe diameters.

TURBIDITY / LIQUID ANALYSIS / CIP

PARTICLE ANALYSIS

Canty’s Mini Inflow product line can be set up in a variety of configurations to be used anywhere within a pharmaceutical process in order to ensure that processes are running at their maximum efficiency and to bring awareness to process upset conditions in real-time.

Canty mini Inflow analyzers utilize the latest in visible-spectrum microscopic imaging technology. Canty’s Gigabit Ethernet cameras, microscopic lenses, trademark fused glass, LED cool lighting systems, and proprietary CANTYVISION Intelligent Analysis software combine to provide the very best in real time analysis of particle concentration and size and shape distributions.

PARTICLE ANALYSIS

The Canty PHARMAFLOW™ provides non-destructive microscopic viewing and delivers particle size analysis with two-dimensional results when used alongside the CantyVisionClient™ Software.