BioTech

Fermenter and Bioreactor control and accessories include the brightest light with the fused sight glass (FuseView). Cameras for Foam Detection & Level Control for complete automation and increased production.

BioTech Applications

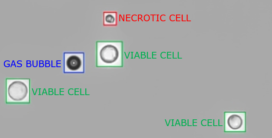

Cell Analysis

Fermentation

Filter Control

Foam & Level Detection

Media Prep

Microspheres

Vessel Monitoring

WFI

Show Less

Pharmaceutical

The safest sight glass (FuseView), and the brightest vessel lights are offered as vessel accessories. Camera imaging is used for Crystallization PSD, Nutsche Filter, Foam Detection, Centrifuge Control.

Pharmaceutical Applications

Glass Manufacturing

High temperature cameras are used in the glass industry on applications such as molten glass level, gob detection, fiber glass flow, stone & width detection, flame detection and many more.

Glass Applications

Chemical

Many applications for the Chemical industry are monitored by camera systems such as foam & level control, extruder, centrifuge, filter dryer cake and thickness monitoring, crystallization, turbidity, and particle sizing systems. Ethylene tube temperature monitoring is done using the high temperature cameras. CANTY has the safest sight glass (FuseView) and brightest light for tanks in the industry.

Refinery - Oil & Gas

Oil in Water and Water in Oil are primary applications. Fuel and Lube Oil quality are easily analyzed using the Inflow. Interface & Phase separation in tank farms.

E & P - Oil & Gas

Applications include Oil in Water(PPM / TSS / PSD) & BS&W(PPM / TSS / PSD).

Exploration & Production Applications

Drilling - Oil & Gas

Lab and Inline concentration & PSD measurement of Drilling Mud. Mud Flow Rate to replace the paddle and Shaker Screen Control are other vision based applications.

Drilling Applications

Food & Beverage

Spray dryer monitoring, particle sizing systems, vessel cameras and level, tank lights & sight glasses, along with defect detection are CANTY applications that are used throughout the industry.

Metal Production

Molten level, slag monitoring, rebar length and cobble detection among others are processes controlled in the metal industry by cameras. Particle size of powder metals by the SolidSizer replaces the need for sieving.

Wastewater

Digester control of foaming is one of the most critical applications in the wastewater industry. Applications range from, foam control, turbidity, clarifier control, and TSS. All these measurements are done using cameras with output to PLC or DCS for complete control and visual verification.

Wastewater Applications

Mining & Aggregate

Cameras are used in a number of applications to optimize the production process within the Mining industry. Applications range from, tailings measurement, at-line / in-line slurry particle analysis systems, turbidity, industrial / lab solid particle sizing systems and vision based froth monitoring systems.

Mining & Aggregate Applications

Chute Plugging

Crusher

Flotation Tank

Lime Kiln

Milling & Blending

Percent Solids / TSS

PSSA

Sand Analysis

Smelter

Smokestack Opacity

Tailings Measurement

Thickener Clarifier

Turbidity

Volume Flow

Show Less

OTHER INDUSTRY

CANTY specializes in many applications across many industries. Please select below to see other applications that may not be listed in other industries.

Other Industry Applications

Latest Posts

11 November 2024 by Colleen Dressel, in Latest posts,Tech

11 November 2024 by Colleen Dressel, in Latest posts,TechJM Canty & NIBRT

JM Canty and NIBRT win Pharma Project of the Year at the Pharma Industry Awards ...READ MORE + 15 September 2022 by Colleen Dressel, in Latest posts,Tech

15 September 2022 by Colleen Dressel, in Latest posts,TechNIBRT announce a second phase of collaboration with JM Canty

This photo was taken during a recent visit by Canty to NIBRT. From left to right...READ MORE + 29 June 2017 by Tod Canty, in Uncategorized

29 June 2017 by Tod Canty, in UncategorizedASTM D02 Award

Tod Canty receives award from ASTM D02 CS96 committee in appreciation of work to...READ MORE +

INDUSTRY 4.0

CANTY is a leader in Industry 4.0 using Process Cameras in every industry. Process Cameras are integrated for increased automation, improved communication and self-monitoring, and production of smart machines that can analyze and diagnose issues without the need for human intervention.

Particle Sizing

Have a need for particle sizing for the Lab and Online? Fill out our Particle Sizing Questionnaire and learn more about our particle sizing systems.

Take the Questionnaire now!

Go Green Projects

Include applications for Oil in Water monitoring for the petroleum industry to make sure discharges are within drinking water limits. Particle size and shape knowledge is critical in maintaining and improving these processes.

Find out more

Historical Accomplishments

NASA's replacement of all sight glasses in the shuttle launch pad fuel lines with Fuseview™ sight glasses. The constant leakage failure prior to Fuseview ™ sight glasses was the number one source of delays.

Find out more