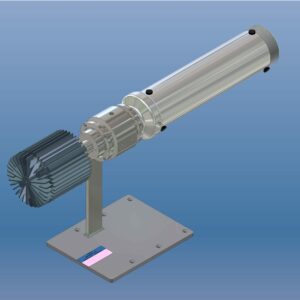

LAB – SOLIDSIZER

The CANTY SolidSizer™ is a vision-based sensor used with the CANTY Vector System image processor for dry particle size measurement in a laboratory environment. The CantyVision™ Software accurately measures multiple aspects of the particles from area / perimeter / minor and major axis / etc. In comparison to a sieve which measures only minor axis the CantyVision™ software can correlate directly to a sieve so the customer does not have to change any QC documents. The SolidSizer™ can correlate within 2% of a sieve. A typical sieve analysis takes anywhere from 20-30 minutes including cleaning and setup for a 70-100 gram sample. On the SolidSizer™ that same sample takes less than 2 minutes. Also multiple screen distributions can be setup to accommodate multiple customers or areas in the process, hence eliminating the need for multiple runs on the same sand for different size distributions. After correlating to current methods of minor axis, customers find benefit in comparing minor axis to major axis and comparing shape factors. Reduce lab time and make sure production samples are not skipped over due to lack of sample time available!

Related ASTM Standards:

- D8200 – Standard Practice for Creating a Correlation to Compare Particle Size Distribution Results of Proppants by Dynamic Imaging Analysis and Sieves. (D18.26)

- D8392 – Standard Practice for Calibration and Verification of Direct Imaging Analyzers Used for Particle Size and Shape Analysis of Catalytic Materials (D32.02)

- E2589 – Terminology Relating to Non-Sieving Methods of Powder Characterization. (E29.02)

Related ISO Standards:

- 9276-6 Representation of results of particle size analysis – Part 6: Descriptive and quantitative representation of particle shape and morphology.

Canty participates in the referenced ASTM subcommittees (D18.26, D32.02 and E29.02) in order to develop useful standards for imaging analyzers. Although the referenced standards are often particular to a type of particle, they can be generalized for use with many types of particles.

ISO9276-6 is widely used to describe shape parameters and provide corresponding formulae for calculation of values.

Product Description

- Correlates to sieve results within 2%

- 2D particle analysis

- 2 min analysis – non destructive

Product Inquiry

Related products

-

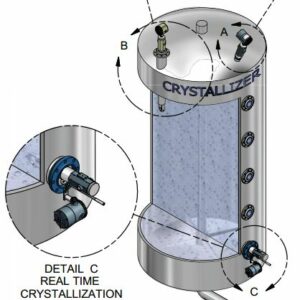

Crystallization

Manual monitoring of a crystallisation process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space, and also ensuring optimum illumination of the area which the operator is viewing.

Process Layout Tab Link

Popup Process Layout