Product Description

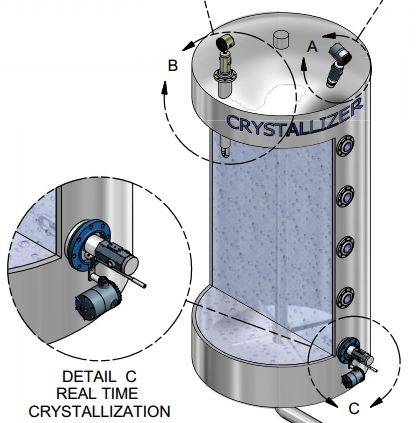

Manual monitoring of a crystallisation process is done through the use of the Canty Fuseview™ and Fibre Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space, and also ensuring optimum illumination of the area which the operator is viewing. Remote process monitoring is possible through the use of a microscopic camera system to allow the user to view the growth of the crystals. The Canty Crystalvision™ range combines Canty’s fused glass and lighting technologies to provide an unrivalled continuous view from initial nucleation, to fully formed crystals, allowing for early problem detection (eg. secondary seeding) and reaction. Cantyvision image analysis software allows for particle size and shape characterization during the initial stages of crystal growth (up to 5% concentration), while the remote view is continuos throughout the process.