CANTY Camera & Light Vision Systems are a patented design to view and illuminate the inside of a pressure or process vessel through a single connection. There is no need for multiple ports! CANTY can supply an integrally mounted camera and light (optional) in flanged, sanitary or NPT threaded process connections. CANTY fused glass technology provides a safe, high pressure, hermetic fused glass barrier between the process and the camera electronics.

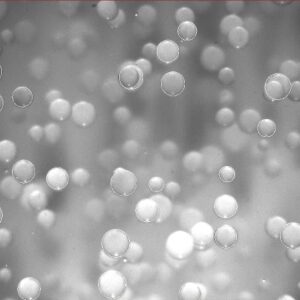

The key to CANTY Camera & Light Vision Systems is the CANTY LED Light. CANTY uses fiber optic light guides to focus cool, effective light into a process or pressure vessel. Cool light eliminates product bake-on, adding no heat to the process. Fiber optic light guides deliver the maximum amount of light into the tank. The resulting live, remote image from a CANTY Camera & Light Vision System is unparalleled!