FIRED HEATERS AND FURNACES

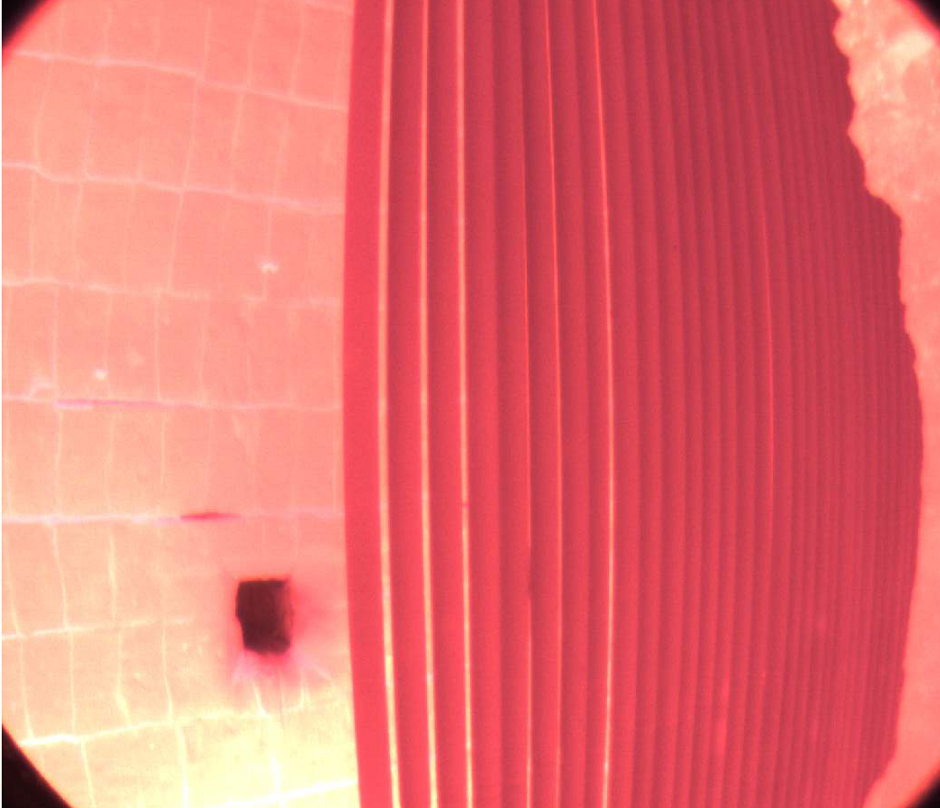

Cracking furnaces are used in a variety of applications such as the production of ethylene, hydrogen, vinyl chloride monomer (VCM), and ammonia. In each of these processes, it is important to measure the the temperatures of the tubes in which the reaction is occurring. This measurement is widely known as tube metal temperatures (TMT’s). CANTY’s high temperature camera systems are installed on these furnaces to obtain video during operation. This video is fed into CANTY’s Smart Tube software to monitor TMT’s, identify hot spots, and even track the position of individual tubes as they shift over time.

Product Description

- Canty Smart Tube software allows up to 6 cameras to be analyzed on one Vector Control Module (VCM)

- High resolution cameras allow for highly accurate analysis across multiple tubes with a single camera

- Significantly less air consumption for cooling than competitive technologies

- Real-time, continuous measurements

- Visual verification of all measurements

- Record video for future reference

1) FIRED HEATERS AND FURNACES BROCHURE

2) CRACKING FURNACE DATASHEET

3) EXTREME TEMP CAMERA DATASHEET

4) QUENCH WATER ANALYSIS SYSTEM

5) PRESENTATION

6) CRACKING FURNACE DIMENSION QUESTIONNAIRE

Tube metal temperature (TMT) analysis

Hot spot alarming alerts to coking or process upsets

Tube position tracking

Quench Water Analysis