MILLING & BLENDING

Canty provides an at line real time slurry particle sizing system to determine the PSD and shape characteristics along with concentration of the mining slurry. Canty’s range of image based particle analysis systems provide true size and shape characterization, with each particle measured under 13 size and shape parameters. This dynamic vision based method replaces and correlates to screen analysis along with giving the operator an unparalleled insight into the process.

MILLING & BLENDING

FLOTATION TANK

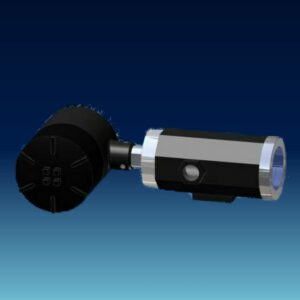

Within the flotation tank, monitoring of the froth characteristics at the surface is highly critical in order optimize yield of the mineral. Canty provide a modular camera light combination unit to provide a remote continuous view and control by detection of froth bubble size, velocity and stability.

FLOTATION TANK

THICKNER CLARIFIER

In order to analyze the performance of the thickener/ clarifier, Canty provide a direct inline color, turbidity and percent solids analyzer, to analyze the fluid discharged from the clarification process, in order to determine if it is within specification. Combining Canty’s imaging, fused glass and lighting technologies, the color of the liquid can be analyzed on a number of color scales (YUV, RGB, Lab), which can be taken as a direct measurement, or related to a specific NTU or FTU turbidity value. The image analysis software has the ability to filter out any air bubbles from the analysis, meaning only a true color / turbidity measurement is performed on the fluid. For immediate detection of any problems within the clarifier, Canty supplies an immersion turbidity / color and percent solids analyzer that can be mounted at various immersion depths to monitor the fluid.

THICKENER CLARIFIER

CRUSHER

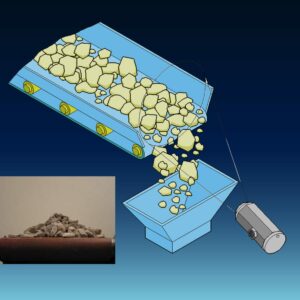

In order to monitor crusher performance, Canty provides Industrial SolidSizer or 3D Rocksizer image analysis systems, which determine if the mining aggregates outputted from the crusher are the correct size and shape. The systems can be run at line through the use of a sweep sampler, or offline as laboratory instruments. In order to know the quantity produced from the crusher, it is important to have an accurate volume measurement. Traditionally, volume belt scales are used, but there can be significant time spent on maintenance of this equipment due to the nature of how the measurement is performed. The Canty Volume Flow system is a non-contact visual measurement of the product area profile on the end of the conveyor. This area measurement can be combined with the velocity of the belt (separate measurement required) in the operators control system, to provide an accurate volume flow measurement.

CRUSHER

TAILINGS MEASUREMENT

For monitoring of tailings outputted from the flotation tank, Canty’s at-line real time liquid particle image analysis systems provide true size, shape and percent solids output providing the operators with the key characteristics of the tailings for optimum operational performance and disposal.

TAILINGS MEASUREMENT

LIME KILN

CANTYVISION can be used to monitor the temperature of the flame and also give visual verification of size. The rotation of the kiln plays a key role in making sure the product is distributed correctly and that the product is not creeping up the side walls too high or too low as that will affect the rate at which the limestone is heating up and ultimately affect the calcination process. CANTYVISION can be used to give visual verification of product.

LIME KILN

SAND ANALYSIS

CANTY specializes in particle size analysis of sand. CANTY can detecting the size and shape of sand and correlate to sieves.