FROTH CONTROL SYSTEMS

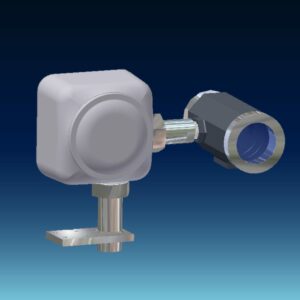

An Ethernet camera is used to provide the measurement image to a customer supplied PC. The image from each camera is dynamically analyzed for bubble size, froth velocity and stability. CantyVision™ software is included with each camera. 4-20mA or OPC output to a PLC or DCS for complete automated control.

Product Description

- Real Time Velocity and Size Froth Control

- 450°F Standard Capabilities (up to 2000°F models available)

- Ethernet color high resolution CCD / CMOS camera includes imaging software.