SPRAY DRYER CAMERA

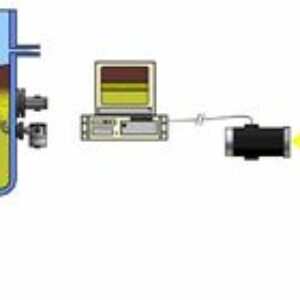

CANTY Spray Dryer Monitoring Vision System can be fully automated by utilizing CANTY VISON™ software to measure the size and shape of the spray pattern profile. OPC UA Modbus or 4-20mA alarms can then be sent to the control system if nozzles clog or the spray pattern changes.

· Fiber optic “cold” light means no product bake-on

· Fused glass interface

· Single nozzle viewing / illuminating

· Maintenance free LED

· Integral cooling chamber

1) 4″ SANITARY SPRAY DRYER-TYPICAL INSTALLATION DETAIL-HAZARDOUS AREA RATED

2) 4″ SANITARY SPRAY DRYER-TYPICAL INSTALLATION DETAIL-WEATHERPROOF/IP

3) RIGHT ANGLE SPRAY DRYER CAMERA TYPICAL INSTALLATION DETAIL