ADHESIVES & RESINS

Canty specializes in many applications for Adhesives & Resins. Some of these include lights / sight glasses, and particle size analysis systems.

ADHESIVES & RESINS

FOAM & LEVEL CONTROL

A camera light combination system is mounted to the centrifuge using the CANTY angled mounting plate. This allows for continuous monitoring from the control room, of initial product filling, the various washing and spinning cycles, and product discharge, therefore enabling greater operator control and efficient identification of any process issues.

CENTRIFUGE CONTROL

CRYSTALLIZATION

Manual monitoring of a crystallization process is done through the use of the CANTY Fuseview™ and Fiber Optic Lighting System, providing the operator with light and sight on one vessel connection, saving space, and also ensuring optimum illumination of the area which the operator is viewing.

CRYSTALLIZATION

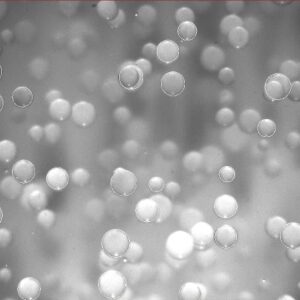

EXPANDED POLYSTYRENE

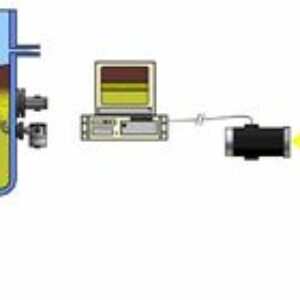

A vessel mount system can be used for real time image capture during the production of polymer beads. The captured images are analysed by CantyVision™ software, to provide a complete bead size distribution through the complete process, allowing for greater control over final product size.

EXPANDED POLYSTYRENE

EXTRUDER CONTROL

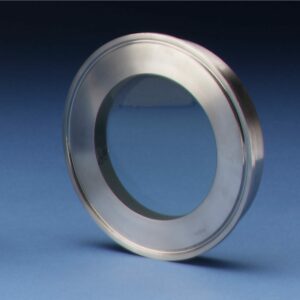

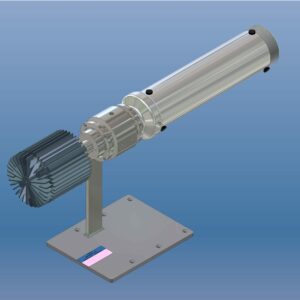

The CANTY extruder vision system allows users to view inside the melt chamber of an extruder at pressures of 5000 psi and temperatures of 600 ºF (300 ºC). This provides a microscopic view of the polymer melt to detect gels, black specks and other impurities in the polymer stream. Strand break is easily detected.

EXTRUDER CONTROL

FILTER DRYER / NUTSCHE FILTER

The latest in imaging camera technology, combined with high intensity LED lighting, is mounted to your filter dryer vessel to provide an unrivalled remote view from the control room into your process.

FILTER DRYER / NUTSCHE FILTER

ETHYLENE FURNACE

The single greatest cause of component failure in Ethylene Furnaces is overheating tubes, which can lead to tube rupture, and possible escape of the feed stock into the firebox area of the furnace, which not only is a process issue, but also a safety issue. The CANTY Ultratemp™ is a vision-based camera system used with the CantyVision to monitor temperature of the tubes inside an ethylene furnace real-time and continuously.

FIRED HEATERS & FURNACES

GROUND FLARES

A flare is used to dispose of flammable material by combustion. Ground flares can be a replacement for a single stack flare for companies. The multi-point ground flares (MPGF) need to be monitored by a camera per EPA regulations. A video camera that is capable of continuously recording (i.e., at least one frame every 15 secs with time and date stamps) images of the flare flame.

FLARE CAMERA

FOAM CONTROL

The CANTY non-contact Ethernet camera mounted on top of the vessel can monitor for level and foam. It can output 4-20mA or OPC to a PLC or DCS for complete control. The control room will have a monitor to view the whole process and provide visual verification.

FOAM CONTROL

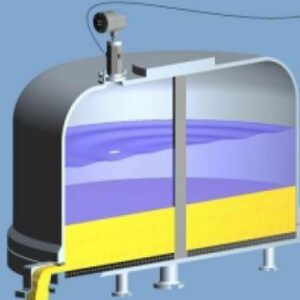

INTERFACE

Monitor phase split in batch mode on organic droplets for increased product recovery. As the droplets appear the system warns of organic phase and the upcoming emulsion. The amount of early droplets and their retraction time will indicate the completeness of the separation. Once the split is identified and stopped, the operator has a visual verification from the video monitor. The color can then be analyzed to ensure there is no inversion.

INTERFACE

LEVEL CONTROL

The CANTY non-contact Ethernet camera mounted on top of the vessel can monitor for level and foam. It can output 4-20mA or OPC to a PLC or DCS for complete control. The control room will have a monitor to view the whole process and provide visual verification.

LEVEL CONTROL

PAINTS & PIGMENTS

This unit covers the determination of particle size distribution and particle shape of paints and pigments by dynamic imaging methods. This method includes the reporting of particles 1 um in size and up to 300 um in size. Used by formulators and QC people in the dispersion of paint and pigments.

PAINTS & PIGMENTS

PHASE SPLIT / INTERFACE / REFLUX CONTROL

Monitor phase split in batch mode on organic droplets for increased product recovery. As the droplets appear the system warns of organic phase and the upcoming emulsion. The amount of early droplets and their retraction time will indicate the completeness of the separation. Once the split is identified and stopped, the operator has a visual verification from the video monitor. The color can then be analyzed to ensure there is no inversion.

PHASE SPLIT

POPCORN POLYMER

CANTY manufactures analyzers designed for the automated early detection of the formation of popcorn polymer.

POPCORN POLYMER

SPRAY DRYER

Monitoring the entire spray drying process will yield high production results. To start by monitoring the turbidity of the liquid going into the dryer will help decrease buildup on the nozzle or imperfections. Using the CANTY light and FuseView will assist on looking into the actual dryer. The CANTY camera and light combo can be used to control and monitor the angle of which the spray comes out of the nozzle. Finally, at the end the SolidSizer with color spec can make sure the particle size is correct and no impurities are forming online.