-

BABY FORMULA

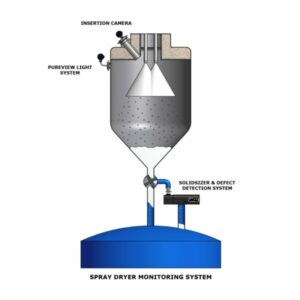

In baby formula processing, viewing spray nozzle patterns is crucial for quality control and optimizing the spray drying process. CANTY’s spray dryer monitoring systems use industrial cameras and light combinations to visualize spray nozzle patterns in real-time. This allows operators to detect changes in the spray pattern profile, clogging, and product build-up before they lead to issues. The system can also be automated to measure the size and shape of the spray pattern, sending alarms to the control system if anomalies are detected.

-

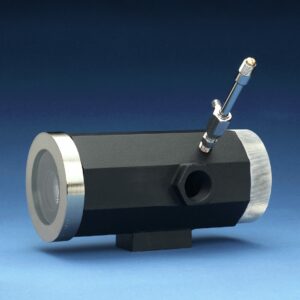

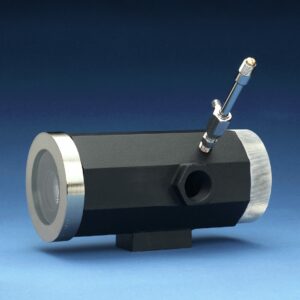

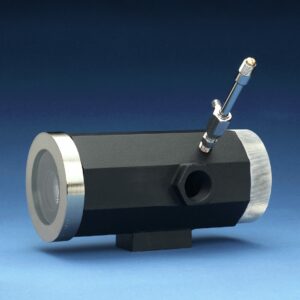

MINI INFLOW

Canty Mini Inflow analyzers utilize the latest in visible-spectrum microscopic imaging technology. Canty’s Gigabit Ethernet cameras, microscopic lenses, trademark fused glass, LED cool lighting systems, and proprietary CANTYVISION Intelligent Analysis software combine to provide the very best in real time analysis of particle concentration & size and shape distributions.

Mini Cell, Minicell

-

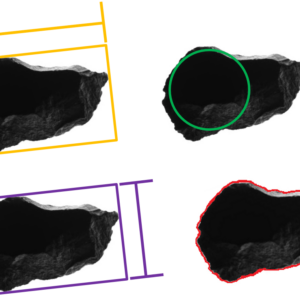

LAB – SOLIDSIZER

The CANTY SolidSizer™ is a vision-based sensor used with the CANTY Vector System image processor for dry particle size measurement in a laboratory environment. The CantyVision™ Software accurately measures multiple aspects of the particles from area / perimeter / minor and major axis / etc. In comparison to a sieve which measures only minor axis the CantyVision™ software can correlate directly to a sieve so the customer does not have to change any QC documents. The SolidSizer™ can correlate within 2% of a sieve. A typical sieve analysis takes anywhere from 20-30 minutes including cleaning and setup for a 70-100 gram sample. On the SolidSizer™ that same sample takes less than 2 minutes. Also multiple screen distributions can be setup to accommodate multiple customers or areas in the process, hence eliminating the need for multiple runs on the same sand for different size distributions. After correlating to current methods of minor axis, customers find benefit in comparing minor axis to major axis and comparing shape factors. Reduce lab time and make sure production samples are not skipped over due to lack of sample time available!

-

INDUSTRIAL SOLIDSIZER™ PARTICLE ANALYSIS SYSTEM

50 um – 2,400 um Particle size analysis range. This system is designed for on-line use to determine particle size, shape and distribution, thereby eliminating the need for sieve analysis.

Related ASTM Standards:

• D8200 – Standard Practice for Creating a Correlation to Compare Particle Size Distribution Results of Proppants by Dynamic Imaging Analysis and Sieves. (D18.26)

• D8392 – Standard Practice for Calibration and Verification of Direct Imaging Analyzers Used for Particle Size and Shape Analysis of Catalytic Materials (D32.02)

• E2589 – Terminology Relating to Non-Sieving Methods of Powder Characterization. (E29.02)Related ISO Standards:

• 9276-6 Representation of results of particle size analysis – Part 6: Descriptive and quantitative representation of particle shape and morphology.Canty participates in the referenced ASTM subcommittees (D18.26, D32.02 and E29.02) in order to develop useful standards for imaging analyzers. Although the referenced standards are often particular to a type of particle, they can be generalized for use with many types of particles.

ISO9276-6 is widely used to describe shape parameters and provide corresponding formulae for calculation of values. -

SPRAY DRYER CAMERA

CANTY Spray Dryer Monitoring Vision System can be fully automated by utilizing CANTY VISON™ software to measure the size and shape of the spray pattern profile. OPC UA Modbus or 4-20mA alarms can then be sent to the control system if nozzles clog or the spray pattern changes.

BABY FORMULA

-

BOTTLE FILLING

CANTY’s Vision Systems are transforming the operations of bottle filling plants by providing advanced real-time monitoring capabilities. These systems excel at accurately measuring fill levels, which ensures that each bottle is filled to the correct specification, minimizing waste and optimizing product quality. Additionally, their ability to detect defects in bottle material helps prevent compromised products from reaching consumers, enhancing safety and customer satisfaction.

Moreover, CANTY’s technology ensures that caps are applied and sealed properly, significantly reducing the risk of leakage and contamination. The systems can also monitor label application and alignment, ensuring that every bottle not only looks good but also meets regulatory compliance and branding standards.

By integrating CANTY’s surveillance cameras with these functionalities, plants benefit from enhanced efficiency and consistency throughout the filling process. This comprehensive oversight minimizes human error and accelerates production speeds, ultimately leading to increased throughput and reduced operational costs. The cumulative effect of these enhancements contributes to a more profitable operation, ensuring that manufacturers can meet demand while maintaining high standards of quality and safety.

-

INDUSTRIAL SURVEILLANCE CAMERAS

Canty Surveillance Cameras are ideal for demanding surveillance applications, visual inspection or verification functions in extreme environments.

- Weather proof, explosion/flame proof housings

- Designed for harsh industrial environments – Heavy duty, rugged enclosures.

- Fused glass provides hermetic seal of the enclosure – no gaskets required

- High Quality cameras, optics for optimum picture resolution

- All cameras, lenses feature state of the art camera technology

- Compact and light-weight

- Various models feature FM, CSA approvals, approval to CENELEC standards

BOTTLE FILLING

-

BREWERY LIGHT

The CANTY Brewery Lighting system is designed to illuminate brewery and beverage vessels. The LED light is a fused glass light which provides a high intensity, cold light source to illuminate the process with a true white light (5000° K color temperature). The cold light ensures that no heat is added to the process, which avoids unaccounted for heat sources in the reaction while also ensuring there is no product bake-on. The LED lighting package provides a compact, cost-effective lighting system to meet all of your sanitary process needs. Each Canty LED light uses a high pressure, high temperature, fused glass hermetic seal to completely isolate the light source from the process. The LED light can mate with a variety of couplings, including Tri-Clamp®, NA-Connect®, Flange and Perlick®.

TA11500-1094 -

BREWING

Canty’s specialized applications in the brewing industry play a crucial role in enhancing the quality and safety of beer production. Key processes such as haze monitoring, turbidity, and yeast cell analysis are essential for maintaining consistent beer quality and ensuring a safe, flavorful product. Canty’s analysis maintain high standards of quality control, leading to a more consistent and enjoyable product for consumers.

-

INFLOW™ TURBIDITY MEASUREMENT SYSTEM

Turbidity analysis uses a high-resolution CCD/CMOS image sensor that detects turbidity changes in fluids by measuring the transmittance of light. Using advanced software algorithms, the system automatically removes gas bubbles from the analysis resulting in highly accurate and repeatable data outputs. This system is designed for inline use with varying pressures, temperatures, and pipe diameters.

-

BIOCAM™ SANITARY PROCESS CAMERA

The CANTY BioCam™ is uniquely qualified to view inside your fermenters and bioreactors and provides a continual control signal allowing the user to meter in antifoam. The BioCam™ is an Ethernet based imaging system which connects to the CANTY VCM™ image processor that determines the percentage of foam on the surface of the liquid. The foam control function allows for significant savings of antifoam, improves process performance in cell culture growth and eliminates the need for additional antifoam fluids in purification. The all in-one design is both compact and sanitary and unlike its predecessors requires no additional external power supply for operation. A built in heater eliminates condensation from forming on the glass and provides for a clear image at all times. Coupled with CantyVision™ software, the BioCam™ can be used for full control via OPC or 4-20mA.

-

MINI INFLOW

Canty Mini Inflow analyzers utilize the latest in visible-spectrum microscopic imaging technology. Canty’s Gigabit Ethernet cameras, microscopic lenses, trademark fused glass, LED cool lighting systems, and proprietary CANTYVISION Intelligent Analysis software combine to provide the very best in real time analysis of particle concentration & size and shape distributions.

Mini Cell, Minicell

-

INFLOW™ PARTICLE SIZING SYSTEM

.7 um – 4800 um Particle size analysis range for inline real time information. This system is designed for inline use with varying pressures, temperatures, and pipe diameters.

-

PROCAM™ SANITARY PROCESS CAMERA

The CANTY ProCam™ is a process camera engineered and designed for sanitary applications. The ProCam™ combines the latest in LED lighting with Ethernet camera technology in a streamlined package.

-

PUREVIEW SANITARY SIGHT GLASS / LED LIGHTING SYSTEM

CANTY fiber optic lighting systems have been designed to provide efficient, high output LED light in a cost effective package. CANTY uses only high quality, fiber optic light pipes to guide the light from our light source through a sight glass or process connection. The light is elliptically focused into the fiber optic light pipe and guided through the sight glass minimizing losses while maximizing your tank or vessel lighting!

-

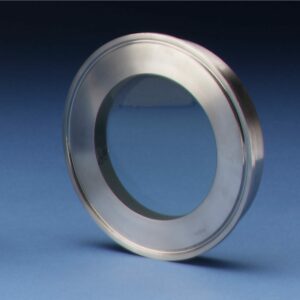

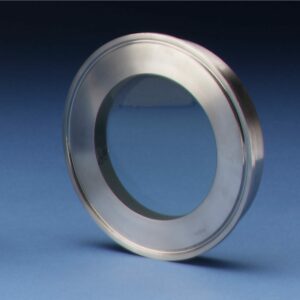

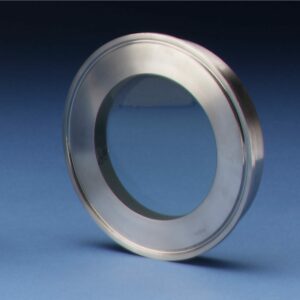

Fuseview™ Sanitary Sight Glass

All CANTY sight glasses feature the Fuseview™ window. Our unique fused glass windows far exceed all conventional tempered glass windows in safety and performance. By fusing glass to metal, a high pressure, high safety, hermetic seal is formed. The fused glass Technology ensures safety with every Fuseview™. What’s more, our windows can easily be removed for cleaning. CANTY windows do not have to be discarded, as do traditional tempered glass windows. CANTY fused glass windows can be re-used again and again.

BREWING

-

Color/Black Spec

Color/Black Spec Analysis refers to the investigation of color/black specks or foreign matter found in food products, often to identify the source of contamination and prevent recurrence. CANTY’s vision systems automate this process, enabling rapid detection and swift removal of contaminants and their source, thereby enhancing food safety efficiency.

-

INFLOW™ COLOR MEASUREMENT SYSTEM

Canty InFlow technology images the fluid to capture color and particle size, shape and distribution if desired. Systems have a fused glass-to-metal, smooth interface with the process which enables use in high temperature and pressure environments, and minimizes maintenance of the interface in extreme environments.

-

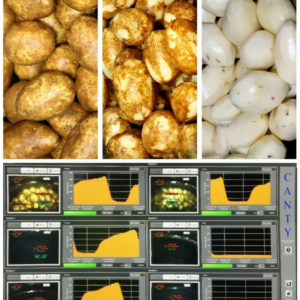

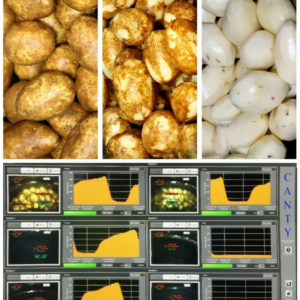

SOLIDSIZER™ WITH COLOR ANALYSIS

10 um – 2,400 um Particle size analysis range. Finished sugar product is subjected to a series of quality control tests in order to determine if the sugar crystals are the correct size and shape, and also that the concentration of black specks / burned sugar crystals is within specification. CANTY’S range of image based particle analysis systems provide true size and shape characterization, with each particle measured under 13 size and shape parameters. CANTY’S imaging systems also offer the option of Black Speck detection within the sugar sample. The systems can be run at line through the use of a sweep sampler, or offline as laboratory instruments. This system provides direct correlation to traditional sieve analysis, but does so in a much shorter analysis time, with much less operator input required.

COLOR/BLACK SPEC

-

PROCAM™ SANITARY PROCESS CAMERA

The CANTY ProCam™ is a process camera engineered and designed for sanitary applications. The ProCam™ combines the latest in LED lighting with Ethernet camera technology in a streamlined package.

-

DAIRY

CANTY is well-known for providing advanced solutions tailored to various dairy applications. These applications contribute significantly to enhancing productivity, quality, and compliance within the dairy industry, illustrating CANTY’s commitment to supporting dairy manufacturers in optimizing their processes.

-

SPRAY DRYER CAMERA

CANTY Spray Dryer Monitoring Vision System can be fully automated by utilizing CANTY VISON™ software to measure the size and shape of the spray pattern profile. OPC UA Modbus or 4-20mA alarms can then be sent to the control system if nozzles clog or the spray pattern changes.

-

INFLOW™ TURBIDITY MEASUREMENT SYSTEM

Turbidity analysis uses a high-resolution CCD/CMOS image sensor that detects turbidity changes in fluids by measuring the transmittance of light. Using advanced software algorithms, the system automatically removes gas bubbles from the analysis resulting in highly accurate and repeatable data outputs. This system is designed for inline use with varying pressures, temperatures, and pipe diameters.

-

Fuseview™ Sanitary Sight Glass

All CANTY sight glasses feature the Fuseview™ window. Our unique fused glass windows far exceed all conventional tempered glass windows in safety and performance. By fusing glass to metal, a high pressure, high safety, hermetic seal is formed. The fused glass Technology ensures safety with every Fuseview™. What’s more, our windows can easily be removed for cleaning. CANTY windows do not have to be discarded, as do traditional tempered glass windows. CANTY fused glass windows can be re-used again and again.

-

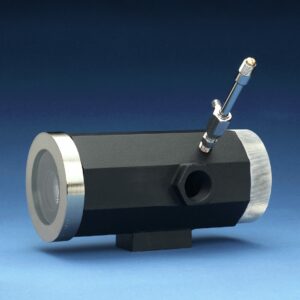

PROCESS CAMERA / LIGHT

View and illuminate inside a pressure or process vessel through a single connection. Integrally mounted camera and lighting system (optional) in a connection as small as a 2” NPT.

-

INDUSTRIAL SOLIDSIZER™ PARTICLE ANALYSIS SYSTEM

50 um – 2,400 um Particle size analysis range. This system is designed for on-line use to determine particle size, shape and distribution, thereby eliminating the need for sieve analysis.

Related ASTM Standards:

• D8200 – Standard Practice for Creating a Correlation to Compare Particle Size Distribution Results of Proppants by Dynamic Imaging Analysis and Sieves. (D18.26)

• D8392 – Standard Practice for Calibration and Verification of Direct Imaging Analyzers Used for Particle Size and Shape Analysis of Catalytic Materials (D32.02)

• E2589 – Terminology Relating to Non-Sieving Methods of Powder Characterization. (E29.02)Related ISO Standards:

• 9276-6 Representation of results of particle size analysis – Part 6: Descriptive and quantitative representation of particle shape and morphology.Canty participates in the referenced ASTM subcommittees (D18.26, D32.02 and E29.02) in order to develop useful standards for imaging analyzers. Although the referenced standards are often particular to a type of particle, they can be generalized for use with many types of particles.

ISO9276-6 is widely used to describe shape parameters and provide corresponding formulae for calculation of values. -

LAB – SOLIDSIZER

The CANTY SolidSizer™ is a vision-based sensor used with the CANTY Vector System image processor for dry particle size measurement in a laboratory environment. The CantyVision™ Software accurately measures multiple aspects of the particles from area / perimeter / minor and major axis / etc. In comparison to a sieve which measures only minor axis the CantyVision™ software can correlate directly to a sieve so the customer does not have to change any QC documents. The SolidSizer™ can correlate within 2% of a sieve. A typical sieve analysis takes anywhere from 20-30 minutes including cleaning and setup for a 70-100 gram sample. On the SolidSizer™ that same sample takes less than 2 minutes. Also multiple screen distributions can be setup to accommodate multiple customers or areas in the process, hence eliminating the need for multiple runs on the same sand for different size distributions. After correlating to current methods of minor axis, customers find benefit in comparing minor axis to major axis and comparing shape factors. Reduce lab time and make sure production samples are not skipped over due to lack of sample time available!

-

PUREVIEW SANITARY SIGHT GLASS / LED LIGHTING SYSTEM

CANTY fiber optic lighting systems have been designed to provide efficient, high output LED light in a cost effective package. CANTY uses only high quality, fiber optic light pipes to guide the light from our light source through a sight glass or process connection. The light is elliptically focused into the fiber optic light pipe and guided through the sight glass minimizing losses while maximizing your tank or vessel lighting!

DAIRY

-

EFFLUENT / CIP

CIP (Clean-in-Place) systems facilitate cleaning and sanitizing equipment without disassembly, reducing downtime and improving hygiene. Effluent treatment plants then address the wastewater generated by CIP and other processing activities, ensuring it meets environmental standards.

-

INFLOW™ COLOR MEASUREMENT SYSTEM

Canty InFlow technology images the fluid to capture color and particle size, shape and distribution if desired. Systems have a fused glass-to-metal, smooth interface with the process which enables use in high temperature and pressure environments, and minimizes maintenance of the interface in extreme environments.

-

INFLOW™ TURBIDITY MEASUREMENT SYSTEM

Turbidity analysis uses a high-resolution CCD/CMOS image sensor that detects turbidity changes in fluids by measuring the transmittance of light. Using advanced software algorithms, the system automatically removes gas bubbles from the analysis resulting in highly accurate and repeatable data outputs. This system is designed for inline use with varying pressures, temperatures, and pipe diameters.

EFFLUENT / CIP

-

FOAM CONTROL

Foam can cause product contamination, reduce processing speed, and even lead to equipment damage, resulting in wasted product and increased costs. Effective foam control is essential for maintaining product integrity, optimizing process efficiency, and minimizing operational expenses. CANTY provides the solution you need to monitor foam in your operation.

-

PROCESS CAMERA / LIGHT

View and illuminate inside a pressure or process vessel through a single connection. Integrally mounted camera and lighting system (optional) in a connection as small as a 2” NPT.

FOAM CONTROL

-

LEVEL CONTROL

Level control is crucial in the food processing industry to ensure product quality, safety, and efficient operation. CANTY Vision Systems can provide accurate level measurement and control systems to help prevent overfilling, which can lead to spills and contamination, and underfilling, which can affect product consistency and safety. Additionally, precise level control is essential for inventory management, minimizing waste, and optimizing resource utilization.

-

INFLOW™ COLOR MEASUREMENT SYSTEM

Canty InFlow technology images the fluid to capture color and particle size, shape and distribution if desired. Systems have a fused glass-to-metal, smooth interface with the process which enables use in high temperature and pressure environments, and minimizes maintenance of the interface in extreme environments.

-

INDUSTRIAL SURVEILLANCE CAMERAS

Canty Surveillance Cameras are ideal for demanding surveillance applications, visual inspection or verification functions in extreme environments.

- Weather proof, explosion/flame proof housings

- Designed for harsh industrial environments – Heavy duty, rugged enclosures.

- Fused glass provides hermetic seal of the enclosure – no gaskets required

- High Quality cameras, optics for optimum picture resolution

- All cameras, lenses feature state of the art camera technology

- Compact and light-weight

- Various models feature FM, CSA approvals, approval to CENELEC standards

LEVEL CONTROL

-

LIQUID ANALYSIS

Liquid analysis plays a role in monitoring and controlling various food processing steps, such as fermentation, pasteurization, and extraction. Through color analysis, turbidity and TSS analysis, CANTY systems ensure that food products are safe for consumption, meet quality standards, and comply with regulations.

-

INFLOW™ TURBIDITY MEASUREMENT SYSTEM

Turbidity analysis uses a high-resolution CCD/CMOS image sensor that detects turbidity changes in fluids by measuring the transmittance of light. Using advanced software algorithms, the system automatically removes gas bubbles from the analysis resulting in highly accurate and repeatable data outputs. This system is designed for inline use with varying pressures, temperatures, and pipe diameters.

LIQUID ANALYSIS

-

PARTICLE SIZE AND SHAPE ANALYSIS (PSSA) IN THE FOOD INDUSTRY

Particle size and shape analysis are crucial in food processing because they directly impact food quality, texture, and functionality. Understanding these parameters helps in optimizing manufacturing processes, controlling product quality, and ensuring customer satisfaction. CANTY manufactures vision-based particle analyzers that are used globally. As the leader in particle size analysis for both lab and online systems, CANTY has a variety of products to measure PSSA in food and beverage production.

-

MINI INFLOW

Canty Mini Inflow analyzers utilize the latest in visible-spectrum microscopic imaging technology. Canty’s Gigabit Ethernet cameras, microscopic lenses, trademark fused glass, LED cool lighting systems, and proprietary CANTYVISION Intelligent Analysis software combine to provide the very best in real time analysis of particle concentration & size and shape distributions.

Mini Cell, Minicell

-

LAB – SOLIDSIZER

The CANTY SolidSizer™ is a vision-based sensor used with the CANTY Vector System image processor for dry particle size measurement in a laboratory environment. The CantyVision™ Software accurately measures multiple aspects of the particles from area / perimeter / minor and major axis / etc. In comparison to a sieve which measures only minor axis the CantyVision™ software can correlate directly to a sieve so the customer does not have to change any QC documents. The SolidSizer™ can correlate within 2% of a sieve. A typical sieve analysis takes anywhere from 20-30 minutes including cleaning and setup for a 70-100 gram sample. On the SolidSizer™ that same sample takes less than 2 minutes. Also multiple screen distributions can be setup to accommodate multiple customers or areas in the process, hence eliminating the need for multiple runs on the same sand for different size distributions. After correlating to current methods of minor axis, customers find benefit in comparing minor axis to major axis and comparing shape factors. Reduce lab time and make sure production samples are not skipped over due to lack of sample time available!

-

INDUSTRIAL SOLIDSIZER™ PARTICLE ANALYSIS SYSTEM

50 um – 2,400 um Particle size analysis range. This system is designed for on-line use to determine particle size, shape and distribution, thereby eliminating the need for sieve analysis.

Related ASTM Standards:

• D8200 – Standard Practice for Creating a Correlation to Compare Particle Size Distribution Results of Proppants by Dynamic Imaging Analysis and Sieves. (D18.26)

• D8392 – Standard Practice for Calibration and Verification of Direct Imaging Analyzers Used for Particle Size and Shape Analysis of Catalytic Materials (D32.02)

• E2589 – Terminology Relating to Non-Sieving Methods of Powder Characterization. (E29.02)Related ISO Standards:

• 9276-6 Representation of results of particle size analysis – Part 6: Descriptive and quantitative representation of particle shape and morphology.Canty participates in the referenced ASTM subcommittees (D18.26, D32.02 and E29.02) in order to develop useful standards for imaging analyzers. Although the referenced standards are often particular to a type of particle, they can be generalized for use with many types of particles.

ISO9276-6 is widely used to describe shape parameters and provide corresponding formulae for calculation of values. -

INFLOW™ TURBIDITY MEASUREMENT SYSTEM

Turbidity analysis uses a high-resolution CCD/CMOS image sensor that detects turbidity changes in fluids by measuring the transmittance of light. Using advanced software algorithms, the system automatically removes gas bubbles from the analysis resulting in highly accurate and repeatable data outputs. This system is designed for inline use with varying pressures, temperatures, and pipe diameters.

PSSA

-

PEELING OPTIMIZATION

CANTY PEELERCAM™ technology can refine the process of removing outer layers from fruits and vegetables to minimize material loss, energy consumption, and labor costs while maintaining product quality and yield.

-

PEELERCAM™

The CANTY PEELERCAM™ can be used to optimize any fruit or vegetable peeling process. Whether running a batch or continuous process, the PEELERCAM™ system can determine when the product has been suitably peeled, therefore avoiding over or under peeling, which ultimately increases product throughput while minimizing product waste.

For batch based abrasive peeling processes such as potato peeling, the PEELERCAM™ system measures the color intensity value (absolute value, 0 – 255), as well as the rate of change (RoC) of that intensity value. As the skin is removed, the intensity value changes, until eventually coming close to flat lining as all of the skin is removed. At this point, the VCM control signal to the DCS would indicate that peeling is complete, so the processed potatoes can be discharged, and the next batch can be introduced.

PEELING OPTIMIZATION

-

POTATOES

In the past 100 years, potato processing has significantly evolved from largely manual labor to highly automated systems with advanced sorting and quality control mechanisms, utilizing technology like optical sorting machines to identify and remove imperfect potatoes, leading to faster, more efficient production and a wider variety of processed potato products with consistent quality.

CANTY’s range of dynamic imaging systems can be used to do just that, by providing unparalleled views into the process, and generating useful data that can be used for process control and optimization. Potato processes where the CANTY vision based instrumentation can be employed include Peel Measurement, Volume Flow, Size and Shape Analysis, Starch Detection and product quality control. Experience real-time decision-making that optimizes your processes while also enhancing productivity and minimizing environmental impact.

-

INDUSTRIAL SURVEILLANCE CAMERAS

Canty Surveillance Cameras are ideal for demanding surveillance applications, visual inspection or verification functions in extreme environments.

- Weather proof, explosion/flame proof housings

- Designed for harsh industrial environments – Heavy duty, rugged enclosures.

- Fused glass provides hermetic seal of the enclosure – no gaskets required

- High Quality cameras, optics for optimum picture resolution

- All cameras, lenses feature state of the art camera technology

- Compact and light-weight

- Various models feature FM, CSA approvals, approval to CENELEC standards

-

PEELERCAM™

The CANTY PEELERCAM™ can be used to optimize any fruit or vegetable peeling process. Whether running a batch or continuous process, the PEELERCAM™ system can determine when the product has been suitably peeled, therefore avoiding over or under peeling, which ultimately increases product throughput while minimizing product waste.

For batch based abrasive peeling processes such as potato peeling, the PEELERCAM™ system measures the color intensity value (absolute value, 0 – 255), as well as the rate of change (RoC) of that intensity value. As the skin is removed, the intensity value changes, until eventually coming close to flat lining as all of the skin is removed. At this point, the VCM control signal to the DCS would indicate that peeling is complete, so the processed potatoes can be discharged, and the next batch can be introduced.

POTATOES

-

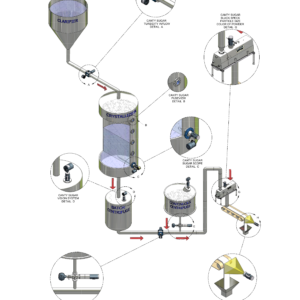

SPRAY DRYING OPTIMIZATION

Monitoring the entire spray drying process will yield high production results. To start by monitoring the turbidity of the liquid going into the dryer will help decrease buildup on the nozzle or imperfections. Using the CANTY light and FuseView™ will assist on looking into the actual dryer. The CANTY camera and light combo can be used to control and monitor the angle of which the spray comes out of the nozzle. Finally, at the end the SolidSizer™ with color spec can make sure the particle size is correct, and no impurities are forming online.

-

LAB – SOLIDSIZER

The CANTY SolidSizer™ is a vision-based sensor used with the CANTY Vector System image processor for dry particle size measurement in a laboratory environment. The CantyVision™ Software accurately measures multiple aspects of the particles from area / perimeter / minor and major axis / etc. In comparison to a sieve which measures only minor axis the CantyVision™ software can correlate directly to a sieve so the customer does not have to change any QC documents. The SolidSizer™ can correlate within 2% of a sieve. A typical sieve analysis takes anywhere from 20-30 minutes including cleaning and setup for a 70-100 gram sample. On the SolidSizer™ that same sample takes less than 2 minutes. Also multiple screen distributions can be setup to accommodate multiple customers or areas in the process, hence eliminating the need for multiple runs on the same sand for different size distributions. After correlating to current methods of minor axis, customers find benefit in comparing minor axis to major axis and comparing shape factors. Reduce lab time and make sure production samples are not skipped over due to lack of sample time available!

-

SPRAY DRYER CAMERA

CANTY Spray Dryer Monitoring Vision System can be fully automated by utilizing CANTY VISON™ software to measure the size and shape of the spray pattern profile. OPC UA Modbus or 4-20mA alarms can then be sent to the control system if nozzles clog or the spray pattern changes.

-

MINI INFLOW

Canty Mini Inflow analyzers utilize the latest in visible-spectrum microscopic imaging technology. Canty’s Gigabit Ethernet cameras, microscopic lenses, trademark fused glass, LED cool lighting systems, and proprietary CANTYVISION Intelligent Analysis software combine to provide the very best in real time analysis of particle concentration & size and shape distributions.

Mini Cell, Minicell

-

SOLIDSIZER™ WITH COLOR ANALYSIS

10 um – 2,400 um Particle size analysis range. Finished sugar product is subjected to a series of quality control tests in order to determine if the sugar crystals are the correct size and shape, and also that the concentration of black specks / burned sugar crystals is within specification. CANTY’S range of image based particle analysis systems provide true size and shape characterization, with each particle measured under 13 size and shape parameters. CANTY’S imaging systems also offer the option of Black Speck detection within the sugar sample. The systems can be run at line through the use of a sweep sampler, or offline as laboratory instruments. This system provides direct correlation to traditional sieve analysis, but does so in a much shorter analysis time, with much less operator input required.

-

INDUSTRIAL SOLIDSIZER™ PARTICLE ANALYSIS SYSTEM

50 um – 2,400 um Particle size analysis range. This system is designed for on-line use to determine particle size, shape and distribution, thereby eliminating the need for sieve analysis.

Related ASTM Standards:

• D8200 – Standard Practice for Creating a Correlation to Compare Particle Size Distribution Results of Proppants by Dynamic Imaging Analysis and Sieves. (D18.26)

• D8392 – Standard Practice for Calibration and Verification of Direct Imaging Analyzers Used for Particle Size and Shape Analysis of Catalytic Materials (D32.02)

• E2589 – Terminology Relating to Non-Sieving Methods of Powder Characterization. (E29.02)Related ISO Standards:

• 9276-6 Representation of results of particle size analysis – Part 6: Descriptive and quantitative representation of particle shape and morphology.Canty participates in the referenced ASTM subcommittees (D18.26, D32.02 and E29.02) in order to develop useful standards for imaging analyzers. Although the referenced standards are often particular to a type of particle, they can be generalized for use with many types of particles.

ISO9276-6 is widely used to describe shape parameters and provide corresponding formulae for calculation of values.

-

HYL 52 SANITARY LED LIGHTING SYSTEM

**New LED Lighting Systems** The HYL 52 LED lighting system is designed to illuminate bio reactors, fermentors and sanitary vessels. The HYL 52 light is a fused glass light which provides a high intensity, cold light source to allow the process to be viewed under a true white light (5000° K color temperature) while adding no heat to the process, which would cause product bake-on. The HYL 52 LED lighting package provides a compact, cost effective, maintenance free lighting system to meet all of your sanitary process needs. No more changing bulbs!

-

Fuseview™ Sanitary Sight Glass

All CANTY sight glasses feature the Fuseview™ window. Our unique fused glass windows far exceed all conventional tempered glass windows in safety and performance. By fusing glass to metal, a high pressure, high safety, hermetic seal is formed. The fused glass Technology ensures safety with every Fuseview™. What’s more, our windows can easily be removed for cleaning. CANTY windows do not have to be discarded, as do traditional tempered glass windows. CANTY fused glass windows can be re-used again and again.

-

PROCESS CAMERA / LIGHT

View and illuminate inside a pressure or process vessel through a single connection. Integrally mounted camera and lighting system (optional) in a connection as small as a 2” NPT.

SPRAY DRYING OPTIMIZATION

-

SUGAR

While the basics of mass sugar refining have not changed significantly in the last 200 years, it is important to take advantage of relatively newer technology to allow the production processes to run more efficiently and produce a higher yield. CANTY’s range of dynamic imaging systems can be used to do just that, by providing unparalleled views into the process, and generating useful data that can be used for process control and optimization. Sugar production processes where the CANTY vision based instrumentation can be employed include clarifying, crystallization, centrifuging, and product quality control.

-

Sugar Pan – Fuseview™

The Fuseview™ eliminates the chance of glass getting into the evaporators or sugar pans by over torque of the operators. Also, it allows for the sugar pan to pull full vacuum unlike tempered glass.

-

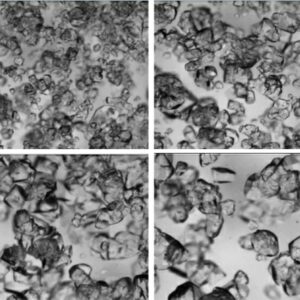

SUGAR PAN – SUGARSCOPE™

Remote process monitoring is possible through the use of the CANTY SugarScope™ which allows the user to view the growth of the sugar crystals in real time. The SugarScope™ combines CANTY’S fused glass and lighting technologies to provide an unrivalled continuous view from initial seeding & nucleation, through to full crystal growth, allowing for early problem detection and increased process control. CantyVision image analysis software can also be used as an add on, allowing for particle size and shape characterization during the initial stages of crystal growth.

-

SUGAR LAB – SOLIDSIZER™ WITH COLOR ANALYSIS

10 um – 2,400 um Particle size analysis range. Finished sugar product is subjected to a series of quality control tests in order to determine if the sugar crystals are the correct size and shape, and also that the concentration of black specks / burned sugar crystals is within specification. CANTY’S range of image based particle analysis systems provide true size and shape characterization, with each particle measured under 13 size and shape parameters. CANTY’S imaging systems also offer the option of Black Speck detection within the sugar sample. The systems can be run at line through the use of a sweep sampler, or offline as laboratory instruments. This system provides direct correlation to traditional sieve analysis, but does so in a much shorter analysis time, with much less operator input required.

-

CENTRIFUGE – CAMERA

CANTY’s dynamic imaging technology uses a combined camera & light system mounted to the top of the centrifuge, to provide a remote view of the process conditions in the control room. The system can also be used in conjunction with CANTYVISION image analysis software to provide important process measurements. In a continuous centrifuge, the system can track the position of the color line, allowing the operator to adjust the feed conditions to maintain a relatively stationary color line position and optimize washing efficiency. In a batch centrifuge, the system can measure the product or “cake” thickness on the basket wall during filling, and determine when the product is dry enough after spinning, to move onto the next production stage without material quality / handling issues that may be caused by high moisture content.

-

SURVEILLANCE CAMERAS

CANTY Surveillance Cameras are ideal for demanding surveillance applications, visual inspection or verification functions in extreme environments.

-

CENTRIFUGE – TURBIDITY MONITOR

The Canty Inflow™ is an excellent tool for controlling a centrifuge to determine percent solids & turbidity of filter breakthrough in the effluent stream, where product is being washed away. This is measured in-line in the effluent stream after the centrifuge.

-

CLARIFIER – TURBIDITY MONITOR

CANTY provides a direct inline color & turbidity analyzer, to analyse the fluid discharged from the clarification process, in order to determine if it is within specification. Combining CANTY’s imaging, fused glass and lighting technologies, the colour of the liquid can be analysed on a number of color scales (YUV, RGB, Lab), which can be taken as a direct measurement, or related to a specific NTU or FTU turbidity value. The image analysis software has the ability to filter out any air bubbles from the analysis, meaning only a true color / turbidity measurement is performed on the fluid.

-

SOLIDSIZER™ WITH COLOR ANALYSIS

10 um – 2,400 um Particle size analysis range. Finished sugar product is subjected to a series of quality control tests in order to determine if the sugar crystals are the correct size and shape, and also that the concentration of black specks / burned sugar crystals is within specification. CANTY’S range of image based particle analysis systems provide true size and shape characterization, with each particle measured under 13 size and shape parameters. CANTY’S imaging systems also offer the option of Black Speck detection within the sugar sample. The systems can be run at line through the use of a sweep sampler, or offline as laboratory instruments. This system provides direct correlation to traditional sieve analysis, but does so in a much shorter analysis time, with much less operator input required.

-

INDUSTRIAL SOLIDSIZER™ PARTICLE ANALYSIS SYSTEM

50 um – 2,400 um Particle size analysis range. This system is designed for on-line use to determine particle size, shape and distribution, thereby eliminating the need for sieve analysis.

Related ASTM Standards:

• D8200 – Standard Practice for Creating a Correlation to Compare Particle Size Distribution Results of Proppants by Dynamic Imaging Analysis and Sieves. (D18.26)

• D8392 – Standard Practice for Calibration and Verification of Direct Imaging Analyzers Used for Particle Size and Shape Analysis of Catalytic Materials (D32.02)

• E2589 – Terminology Relating to Non-Sieving Methods of Powder Characterization. (E29.02)Related ISO Standards:

• 9276-6 Representation of results of particle size analysis – Part 6: Descriptive and quantitative representation of particle shape and morphology.Canty participates in the referenced ASTM subcommittees (D18.26, D32.02 and E29.02) in order to develop useful standards for imaging analyzers. Although the referenced standards are often particular to a type of particle, they can be generalized for use with many types of particles.

ISO9276-6 is widely used to describe shape parameters and provide corresponding formulae for calculation of values.